The customer asked for clarification about the FF/RWD issue on the cassette machine, and I thought I’d share the details here for everyone, since I’m nerding out on it.

I ordered and replaced four belts: the capstan belt, the takeup drive belt, the sensing belt, and the counter belt. I had assumed that replacing the belts would resolve the FF/RWD issues. It turns out that none of these belts is responsible for the fast forward or rewind of the cassette. Instead, this is handled by a separate motor and drive mechanism.

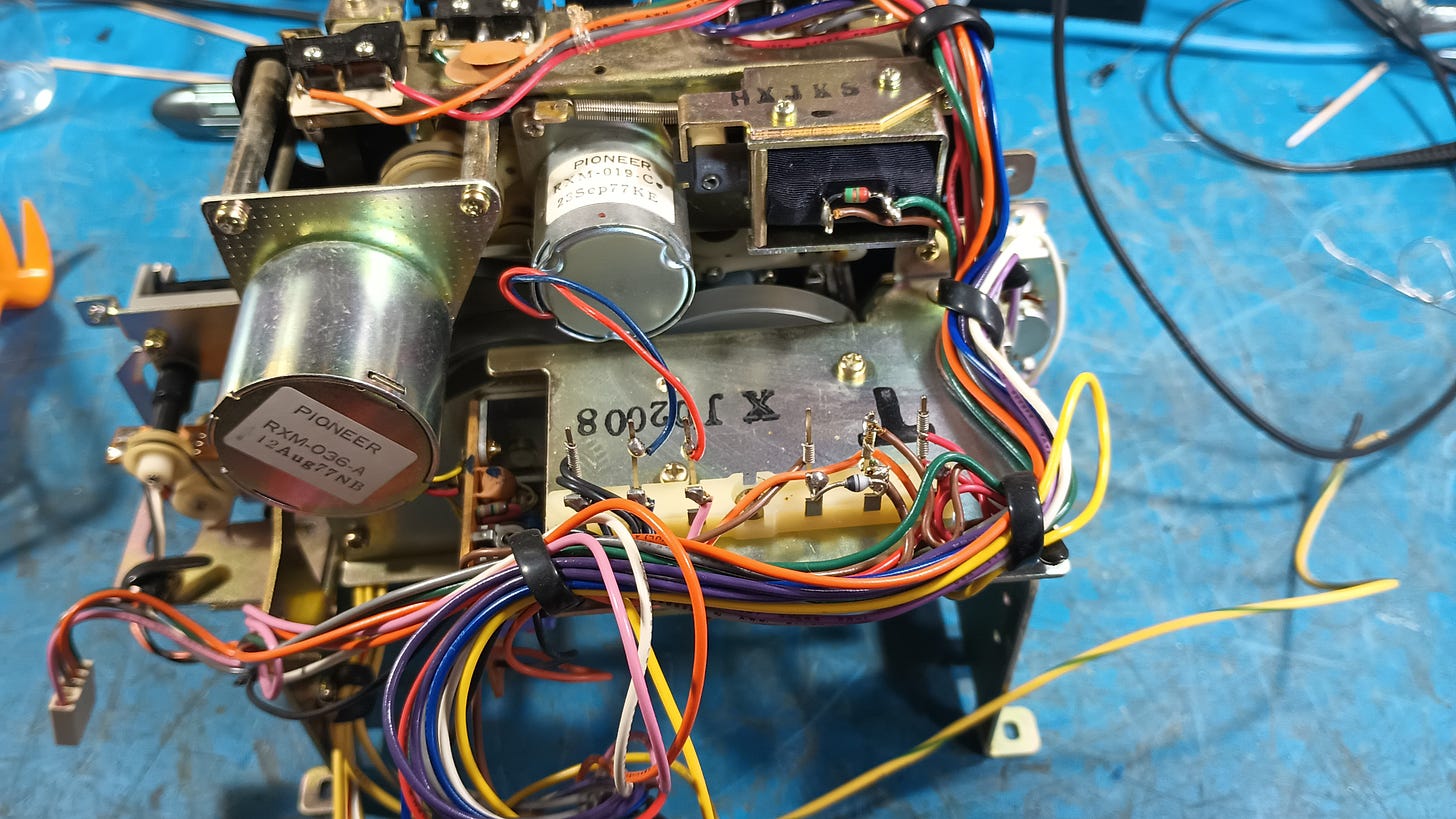

The larger motor on the left is the capstan motor. It’s what turns the capstans that pull the tape across the heads. It also drives the takeup spindle so the tape gets wound up after getting played.

The smaller motor in the center is the FF motor. It runs the fast-forward and rewind functions. Just to the right of it is the solenoid.

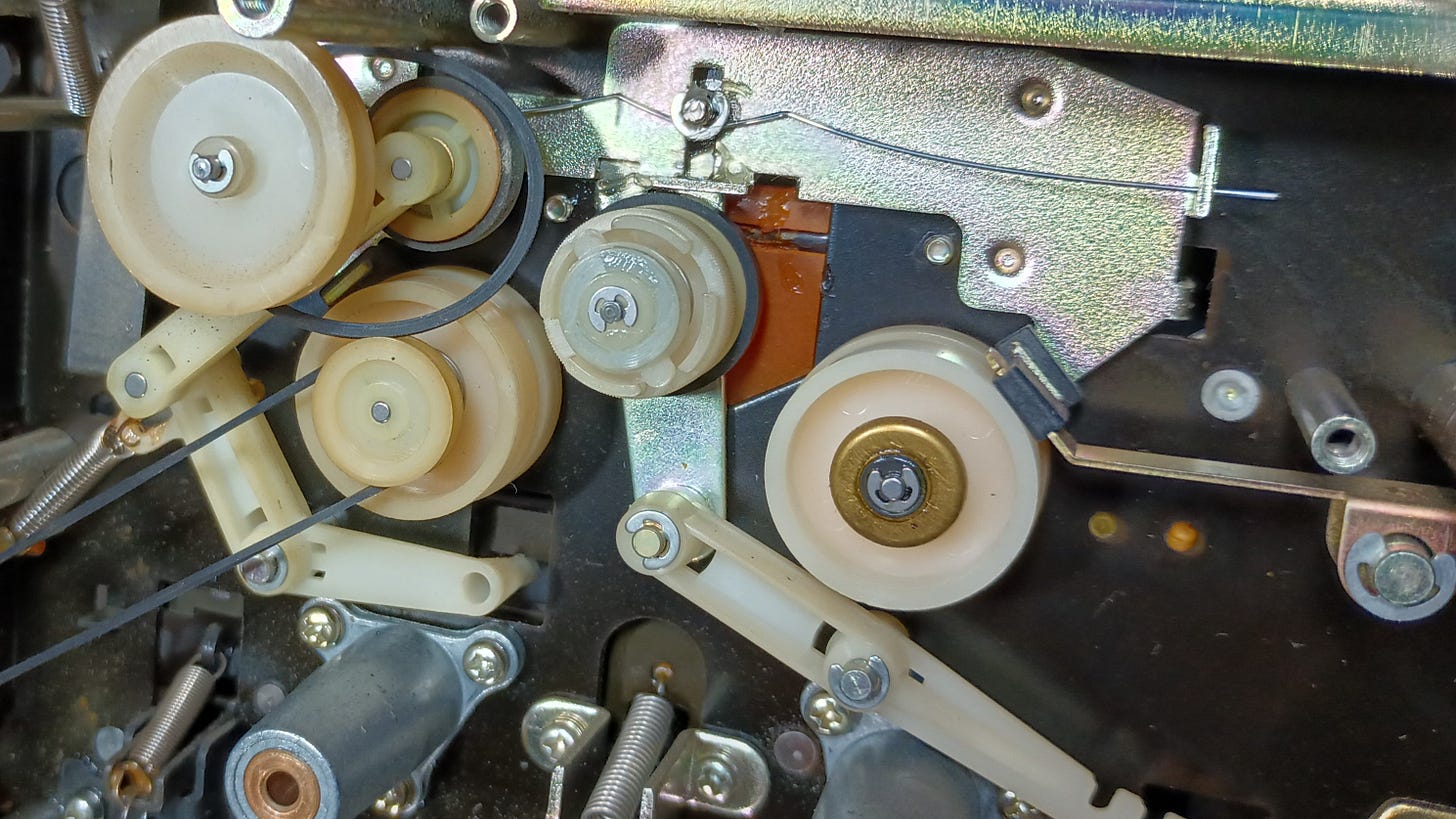

The FF motor is shown here with its pulley, and the takeup and supply reel base assemblies. The FF drive assembly is at lower left, on a shaft on an arm.

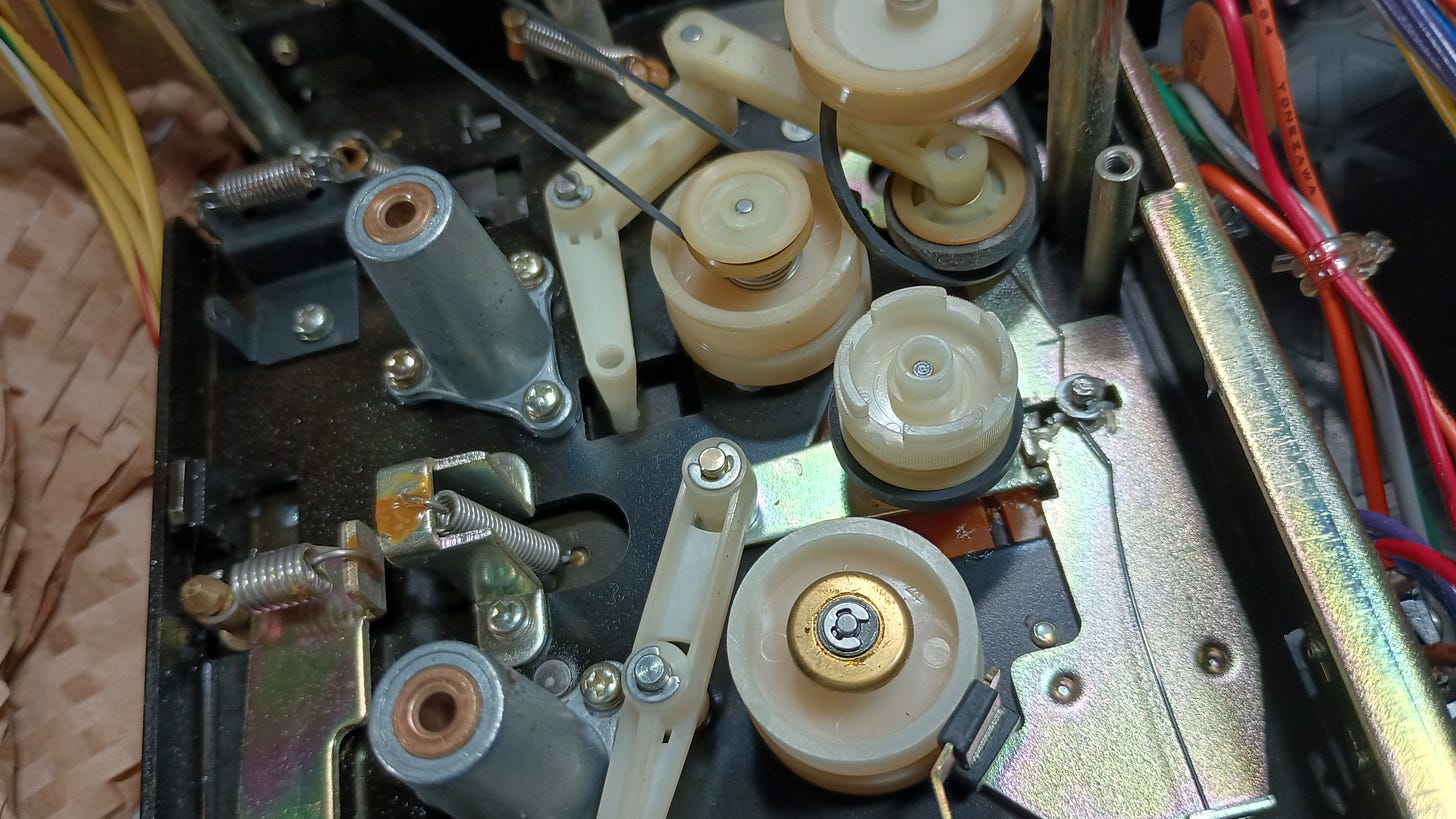

With the motor and solenoid removed, we see the FF drive assembly in the middle, and the takeup and supply reels to either side of it and a little below it. When the motor is installed, its rubber pulley drives the edge of the plastic pulley that’s closer to us. The rubber rim behind it drives the takeup or supply reel in the appropriate direction.

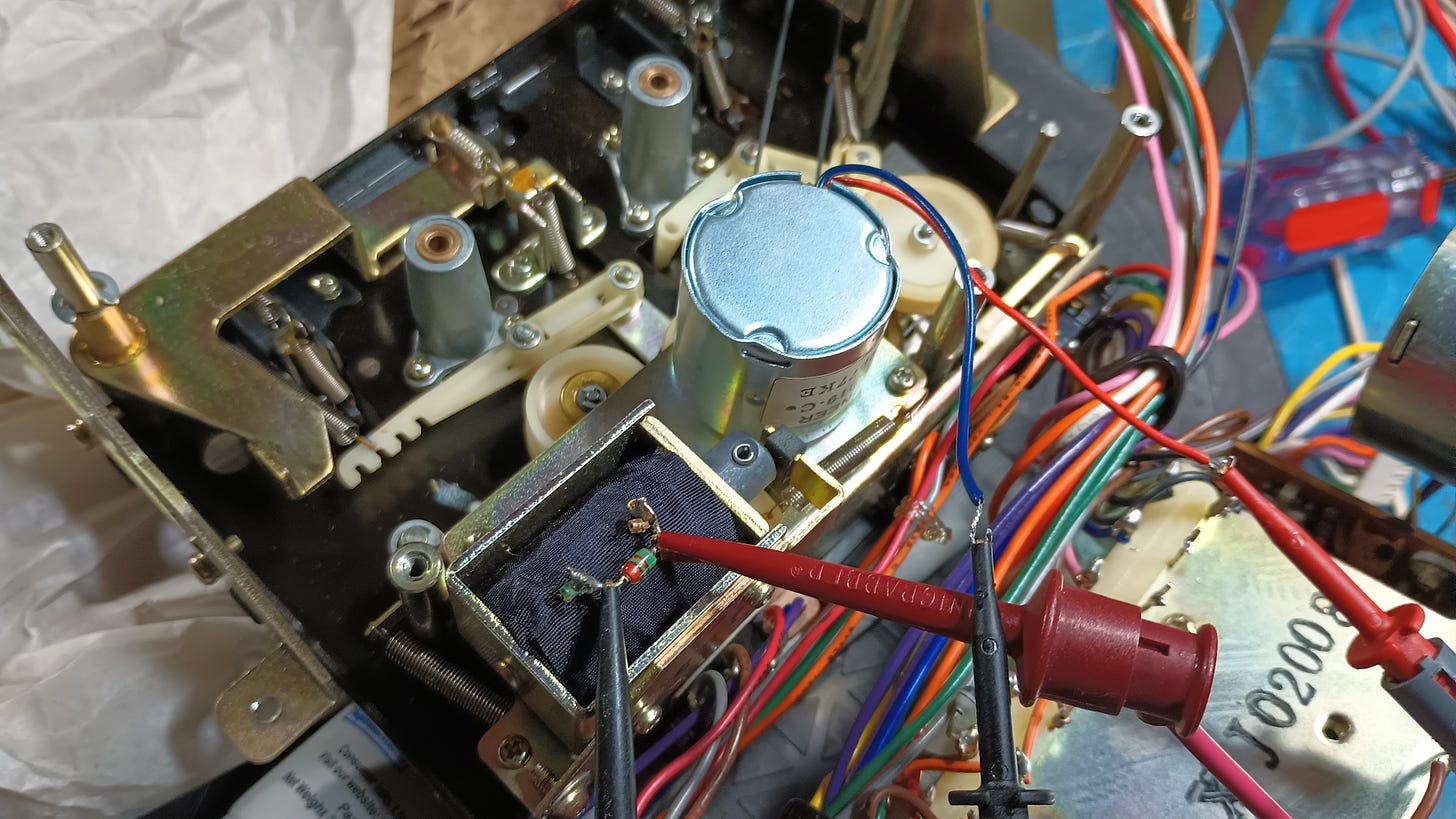

Here’s where my failure to understand the mechanism led me astray and ultimately made the repair take longer than needed. I had thought that the solenoid was responsible for moving the pulley to the takeup or supply reel, but it isn’t. All it does is release the brake and slightly increase the engagement of the pulley with the motor.

Here’s where having a bench supply is useful: I set it up to test the function of the motor and the solenoid in situ. 10V on the solenoid gets it to move the lever, and 12V on the FF motor runs it. This revealed to me that the FF pulley was basically not turning at all.

I took it apart to find out why not, and after examining it several times I lost some of the parts over my shoulder.

At this point I put it down and stepped back to consider, and upon that consideration I think the problem may be either a glazed rubber sleeve on the motor or the rubber tire that drives the reels. That’s my next point of investigation.

The missing pieces are the fourth, fifth and sixth from the right end. If they are truly lost, I could machine them, but I’d rather find them if I can.

Thanks for tuning in to this extra edition.

Great post. I had no idea how intricate the internals were of the CT-F1000. I have one that I am trying to get refurbished and was kind of shocked about the price of repair.

I've ran into a problem though: The capstan motor is toast. I was told this part is very hard to find and I have not had much luck in finding a replacement or a place to get it repaired. Do you know of any repair shop that can refurbish the motor or what a suitable replacement for it might be?